The Everyday Dopp in Progress

We're often asked to share more insight into the process behind creating our products - and we're always happy to do so. There's a lot of work that goes on behind the scenes, and we love sharing more about what it takes to bring our products to your doorstep.

We've been working on bringing The Everyday Dopp to life for over a year, and we're excited that it's almost here. Here's a bit more about the creation of our biggest leather project to date.

First, an "after" shot. Here's what The Everyday Dopp looks like in all it's glory, once complete:

And following are some photos of work in progress.

The Dopps are constructed in stages. The "lid" is assembled first, then the "bucket", and then the two are sewed together. The zipper pouch is also assembled in a separate stage.

First up, the lid. After the leather is cut, the zipper is prepped for assembly. This is a bit more difficult than it looks because there are some difficult curves the zipper has to go around - and if any part of the zipper is off by a fraction of an inch, it won't close properly:

Here, the lids have been glued together and are awaiting sewing (plus awaiting pockets). We use a high strength leather glue to assemble the pieces because they are basically impossible to sew together without being held in place. Rest assured, your Dopp is never coming apart:

Here are some glued lids and side skirts, also awaiting sewing (you can see there isn't any thread in the pieces yet). These are in Bourbon. Notice our custom spec'd YKK zippers. Also notice that we don't paint the edges of the leather on The Everyday Dopp. That's because we use full-grain leather that is tanned all the way through, and have nothing to hide:

More side skirts (these are in Dark Brown):

Time for sewing! We use industrial machines that can handle the extra thick, full-grain leather. (The first prototypes we ever made were on a tiny Singer sewing machine. The results were not pretty.) It takes muscle to work these babies.

Now, we have a fully assembled lid and side skirt, along with attached zipper and pockets. Looking good!

Lids on lids on lids:

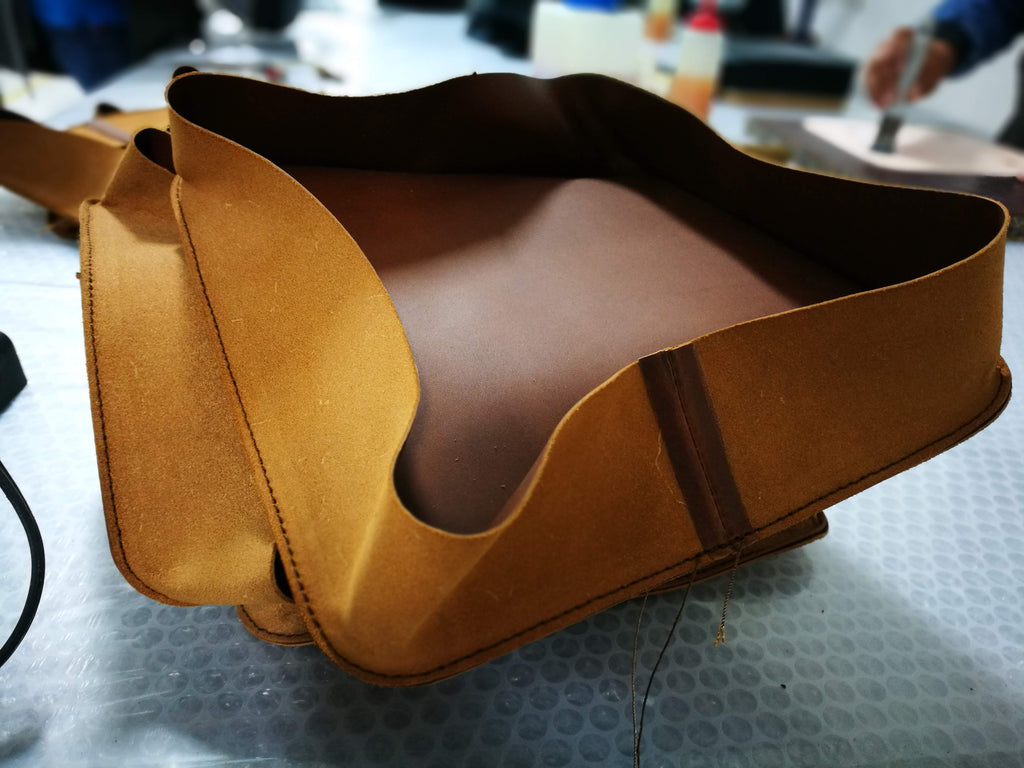

Now, onto the bottom of the Dopp, or the "bucket." This part is a little easier (but not much), because there isn't a zipper involved (it's already attached to the lid). This is the outside bottom piece of the Dopp. It's sewed inside out, so that you don't see the stitches when it's finally assembled:

This is a thick backer that is placed in between the two layers of leather on the bottom of the Dopp. It's required to keep the bottom tray rigid enough to hold your gear without flopping all over the place. Notice there are four holes for the magnets that hold the zipper case in place.

It's a little difficult to explain what's going on in this next picture, but here goes... You're seeing the bottom of the Dopp turned inside out here, and placed on a form to hold it rigid. The shiny surface you're seeing is glue that is used to secure the backer from the previous picture. Once that dries, the backer is covered with another layer of leather. Remember, the Dopp is lined inside and out with leather.

Now on to the zipper pouches. Here are the top pieces after construction. Notice that the edges of the leather are shaved down thinner than the rest of the leather. That's because the thickness of the leather we specified is too thick to be sewn together as required, so the edges of the leather are shaved down with a razor blade.

(Funny story, the blade used to shave the leather is the same size as the blades used in The Single Edge - BUT they are not intended for shaving. Or vice versa. We once got a bad review from a customer who bought our razor blades for leather working.)

Partially assembled zipper cases. Just like the Dopp, these are assembled inside out so that the seams don't show from the outside. Also, they are lined on the inside with leather (it's a lot of leather, I know).

Some completed zipper pouches in Midnight Black:

And just because it's fun, here are some more pictures of the sewing. We use high-strength industrial polyester thread for all seams (instead of the cheaper cotton or nylon counterparts). The men and women who work these machines are true artisans.

After completing assembly, the Dopps are packed up and shipped to our warehouse in Texas, and then sent to you, all over the world. Here's another view of the final product:

We hope you enjoyed this sneak peek behind the scenes! Sound off below in the comments if you have any questions or thoughts to share with us.